Motion Control Systems

Motion Control Systems

Motion Control Systems

Motion Devices

Each material used for mechanical components in motion control has its own unique set of advantages and disadvantages. Table 1 provides a summary of the properties of the most commonly used materials in motion mechanics. Stiffness is a measure of the amount of force required to cause a given amount of deflection. Young's modulus is a material-dependent constant that quantifies the stiffness with large values indicating greater stiffness. Thermal expansion is the change in size or shape of an object, such as a stage, due to a change (increase or decrease) in temperature. When temperature change across a component is non-uniform, such as when a heat source like a laser diode is present, a material which does not dissipate heat may be susceptible to distortions caused by thermal gradients. In this case, the relative thermal distortion, i.e., ratio of the coefficients of thermal expansion to thermal conductivity, becomes important with lower values being preferred. Aluminum is a lightweight material, with good stiffness-to-weight ratio, and has low thermal distortion. It is also fast-machining, cost-effective, and does not rust. However, anodized surfaces are highly porous, making them unsuitable for use in high vacuum. Steel has very good stiffness, good material stability, low thermal expansion, and is well suited to high vacuum applications. Machining of steel is much slower than aluminum, making steel components considerably more expensive. Corrosion of steel is a serious problem, but stainless steel alloys can minimize these problems. Brass is a dense material and fast machining. The main use of brass is for wear reduction where it can be used to avoid self-welding effects with steel lead-screws or shafts. Brass has a less desirable stiffness-to-weight ratio and does not have ideal thermal expansion or thermal conductivity properties. Granite is an extremely hard material allowing polishing to very flat surfaces, which is beneficial in positioning accuracy and repeatability of a total system. Granite also has a very low thermal expansion coefficient. However, for large structures and table surfaces, the mass of a granite structure can become impractically large.

| Parameter | Steel | Aluminum | Brass | Granite |

|---|---|---|---|---|

| Young's Modulus (stiffness), E, Mpsi (GPa) | 28 (193) | 10.5 (72) | 14 (96) | 7 (48) |

| Thermal Expansion, a (µin/in/°F) | 5.6 | 12.4 | 11.4 | 4 |

| Thermal Conduction, c (BTU/hr-ft-°F) | 15.6 | 104 | 67 | 2 |

| Specific Stiffness, E/ρ | 101 (25.4) | 108 (27.7) | 45.6 (11.3) | 70 (17.8) |

| Relative Thermal Distortion, a/c | 0.36 | 0.12 | 0.17 | 2 |

| Density, ρ, lb/in3 (gm/cc) | 0.277 (7.6) | 0.097 (2.6) | 0.307 (8.5) | 0.1 (2.7) |

Table 1. Properties for common stage materials.

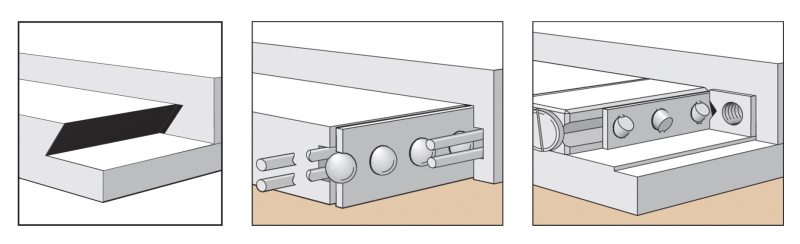

The load and trajectory performance of a translation or rotation stage is primarily determined by the type of bearing or flexure used. Bearings are the preferred mechanism since they provide smooth low-friction rotary or linear movement between two surfaces. They are the primary elements that determine the runout errors of a stage, define the stiffness, and the static load capacity of a stage. Bearings employ either a sliding (dovetail) or rolling action (ball or crossed-roller) as shown in Figure 1. In both cases, the bearing surfaces must be separated by a film of oil or other lubricant for proper performance. Dovetail slides are primarily used for manual positioning and consist of two flat surfaces sliding against each other. They can provide long travel, and have relatively high stiffness and load capacity. However, they do possess high stiction, and the friction varies with translation speed, which makes precise control difficult and limits sensitivity. Ball bearing slides reduce friction by replacing sliding motion with rolling motion. Balls are constrained by vee-ways or hardened steel rods and the friction is very low, resulting in extremely smooth travel. Since the contact area available to transmit loads is smaller in vee-groove bearing ways, ball bearings have a lower load capacity than crossed-roller or other bearings. In order to carry the same sized load, the balls would need to be larger in diameter or be greater in quantity. Crossed-roller bearings offer all of the advantages of ball bearings but with higher load capacity and higher stiffness. This is a result of replacing the point contact of a spherical ball with the line contact of a cylindrical roller. Due to the averaging characteristic of line contacts, angular and linear deviations are generally lower than those found in ball bearings. However, crossed-roller bearings require more care during manufacture and assembly resulting in higher costs. A flexure mechanism uses the elastic deformation of a material (typically a high-strength steel spring) to provide translation. This mechanism requires no lubrication and is virtually free of the stiction normally associated with bearings. However, when used in a translation stage, travel range is limited to just a few millimeters. Also, care must be taken so that permanent deformation does not occur, causing reduced functionality. In addition to these mechanical bearings, air bearings can also be used which provide a low-friction interface via a thin film of pressurized gas.

Motorized Drivers

A motor driver receives input signals from a controller and converts them to power to drive a motor. A motor driver can be a simple amplifier or it can be an intelligent device that can be configured through software for varying operational parameters. Different motor drivers support the different types of motors used in motion control. The stepper motor driver receives input signals from the motion controller commanding it to step the motor to a commanded position. The driver then applies current to the stepper motor windings in order to move the stepping motor to the next step or increment. Drivers for DC motors simply convert a -10 V to +10 V analog control signal from the motion controller to a usable current to drive the motor. Most brushless DC motor drivers are simple amplifiers that convert control signals from the motion controller to a usable current to drive the motor, with the motion controller providing the motor commutation.

Electronic Controllers

- Trajectory generation for moving devices from one point to another or for coordinating the motion of multiple devices

- An interface to let users configure and command the motion system to perform various tasks

- Monitoring end-of-travel limits, amplifier faults, feedback errors, etc. for safety of the system

- Digital input/output lines to synchronize external events to motion or vice versa

- Memory for storing and running on-board motion programs

Furthermore, the output of the motion controller can be configured depending upon the type of motor used to move a motion device.